Cepex PVC fittings stand out for their quality, reliability and durability, as well as the guarantee with multiple certificates: AENOR, AFNOR, NF...

PVC flanges are removable accessories that allow joining pipes, in this case we have a kit of accessories used for the assembly of the butterfly valve and is composed of flange holder sleeve, mobile flanges and screws.

Discover our complete catalog and the technical characteristics in our tables. You will be able to adapt your installation with different sizes from 63 mm diameter to 250 mm diameter.

Thanks to the PVC-U materials it is made of, it can be used in water, chemical and waste pipelines, among other sectors.

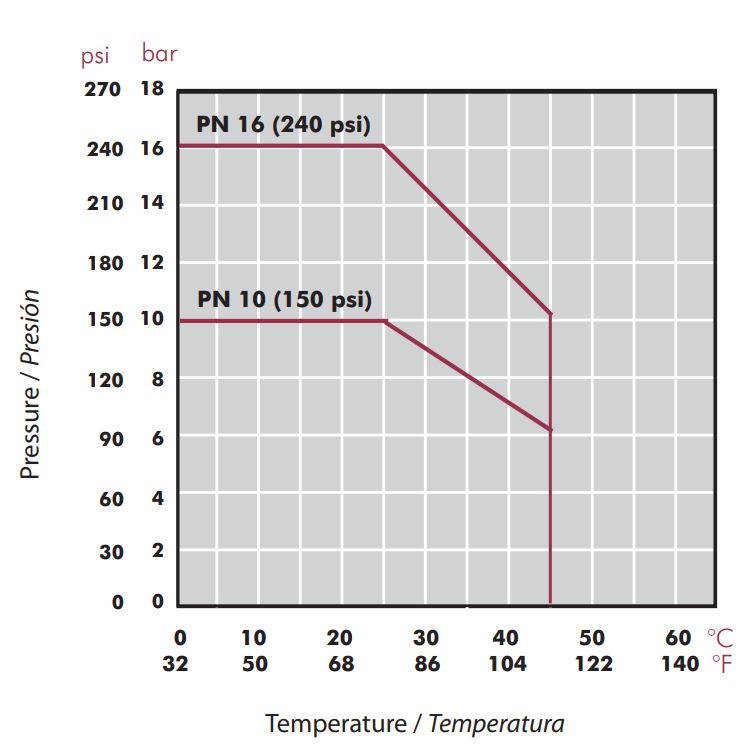

See the following table for the outside diameter and normal pressure of the butterfly valve assembly kit:

Flange mounting allows the mechanical connection between two elements of the installation. It is possible to combine different types of plastic or to join plastic elements with metal ones.

The flange connection requires two flange sleeves. There should be one flange on each side of the joint, which should have the same standard dimensions and hole layout. In this way the two flanges can be fastened together by means of bolts with matching holes.

It is important to take into account:

Steps to follow for a correct assembly: