- DRP 200 seals VITON (FPM): DRP200NHH0000

- DRP 200 seals EPDM: DRP200NHH1000

Seko metering pumps are the ideal solution for precise metering of liquids in ducts and pipes. From small pools to large aquatic installations, both indoors and outdoors, the Seko line of metering pumps offers versatility and reliable performance. These devices can measure a wide range of critical parameters, such as pH, ORP, conductivity, chlorine, oxygen, turbidity, ozone, bromine, and more, depending on the model selected.

In this product sheet you will find a detailed list specifying the compatibility of the metering pump bodies, seals and tubing with various chemicals. This ensures efficient and safe performance when dosing specific substances, providing peace of mind and confidence in your operation.

Kompact Series metering pumps offer an efficient solution for a variety of applications. Solenoid driven, this series provides a constant flow rate, adjustable via a dial on the front panel to suit the user's specific needs. They stand out for their exceptional reliability and ensure optimum performance even in environments exposed to chemical liquids.

The Kompact Series offers a variety of options to meet the specific demands of each context. Depending on the field of application, you can choose from Kompact AMS, AML, DPT and DRP, each with features that allow you to adjust pressure, flow rate and other features to your exact needs.

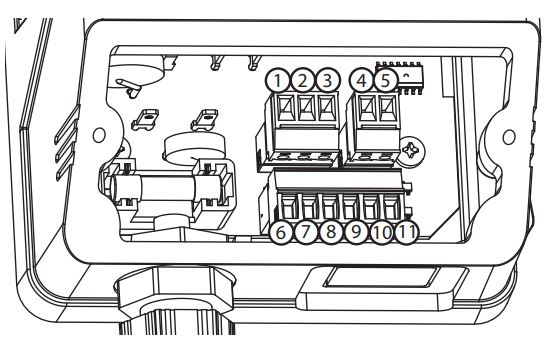

The pump includes the following inputs (accessories not included):

|

1 2 3 |

PT100 Temperature probe input |

|

4 5 |

pH or Redox probe input | |

|

6 7 |

Level control probe input | |

|

8 9 |

Remote Control input | |

|

10 11 |

Flow sensor input |

Pump operates in constant mode

The pump measures and controls the pH value of a solution by programming a series of parameters

The pump measures and controls the ORP value in a solution by programming a series of parameters

Allows setting the maximum flow rate of the pump and the programmed mode.

Allows to set the delayed start-up operation of the pump. This delay is only performed if the pump is turned off and then turned on by disconnecting the power supply.

Allows to configure the delay of the pump operation after the calibration probe (ORP or pH). The delay can be disabled, turned off or can be set from 1 to 60 minutes.

The cc/stroke value can be entered manually or automatically where the pump runs 100 strokes and at the end of these it enters the amount sucked in by the pump.

| Model | Pressure | Flow rate | cc/stroke |

Injections/minute |

Connections (mm) |

|

| bar | l/h | Suction | Discharge | |||

| 200 | 10 | 3,0 | 160 | 0,31 | 4/6 | 4/6 |

| 8 | 5,0 | 0,52 | ||||

When selecting the metering pump model or its spare parts, it is essential to take into account the coding found on the side label. This coding not only identifies the model, but also provides crucial information, such as hydraulic characteristics, materials of the different components, power supply...

We consider the model DRP200NHH0000 to explain the coding:

1. The first field corresponds to the model: DRP

2. The second field corresponds to the hydraulic characteristics: 200

3. The third field refers to the voltage of the dosing pumps: N

4. The fourth field refers to the head material: H

5. The fifth field refers to the installation kit: H

6. The sixth field refers to the seals: 0

The seals are crucial components in a dosing pump, and their choice must be based on the nature of the liquid to be dosed. We recommend that you consult the compatibility table to identify the most suitable seals according to the type of liquid you are dosing.

7. The seventh field is standard: 0

![]()

8. The eighth field refers to customizations:00

|

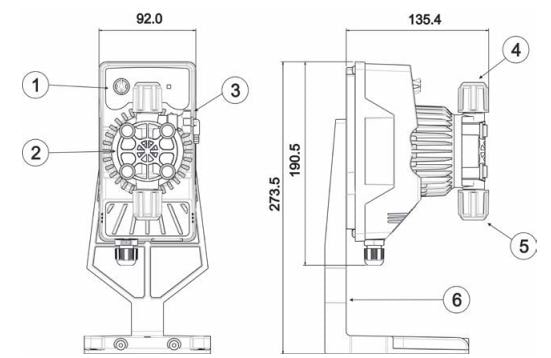

1 | Adjustment area |

| 2 | Dosing head | |

| 3 | Priming valve | |

| 4 | Discharge connection | |

| 5 | Suction fitting | |

| 6 | Mounting bracket |