PVC water stopcock

The ball valve or stopcock is the perfect PVC-U accessory to control the water flow and to be able to open and close it when needed.

Cepex offers a complete range of ball valves in different materials (PVC-U , PVC-C) and different lines of valves in different standards (Metric, BSP, ASTM, NPT, JIS) to adapt to the demands and needs of each market.

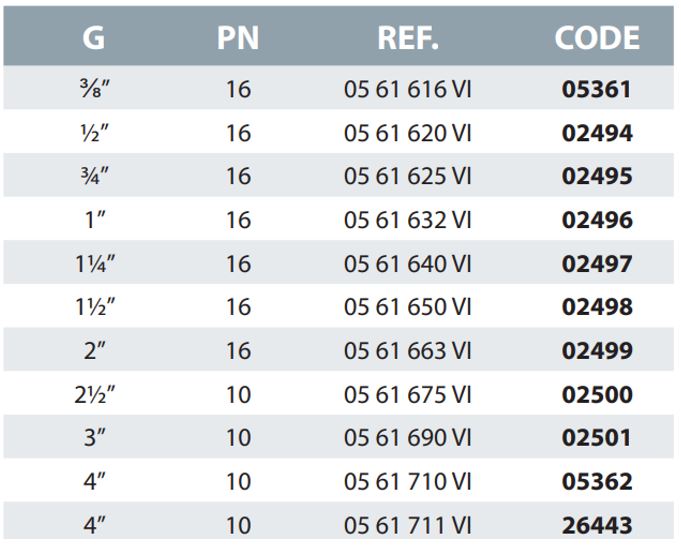

We have a wide range of dimensions and combinations to adapt the installation to your needs from 3/8" to 4. With nominal pressures of 10 and 16.

Cepex fittings provide both pressure and chemical resistance, allowing their use in water, chemical and waste pipelines, among other sectors.

Features PVC-U ball valves - Standard Series

- Antiblock" system that prevents the ball from blocking.

- 100% factory tested

- Minimal pressure drop

- Low opening and closing torque

- Resistance to multiple inorganic chemicals

- Excellent handling characteristics

Specifications standard ball valve thread

- PVC-U body

- Female thread

- Metric series

- PTFE ball seat seals

- O-rings in FPM (Viton)

- Green label: FPM seals, choose according to the fluid.

Note: It is important to choose the type of valve according to the fluid and therefore to choose between EPDM or FPM (Viton) seals.

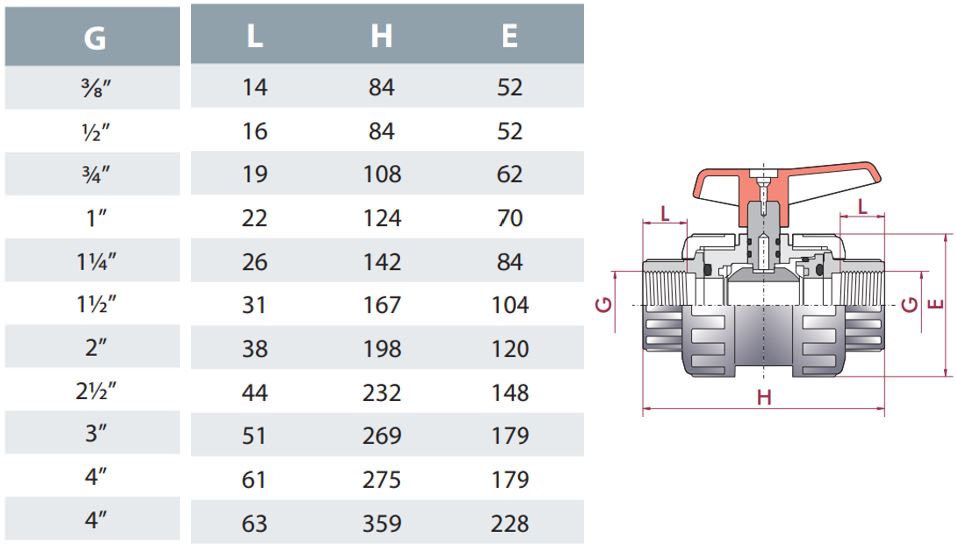

Dimensions ball valve PVC Teflon-FPM threaded

The following table shows the outer diameter, the normal pressure, and the references of the PVC Teflon-FPM ball valve to be threaded:

Consult the following table for the dimensions of the Teflon-FPM PVC ball valve according to the outside diameter.

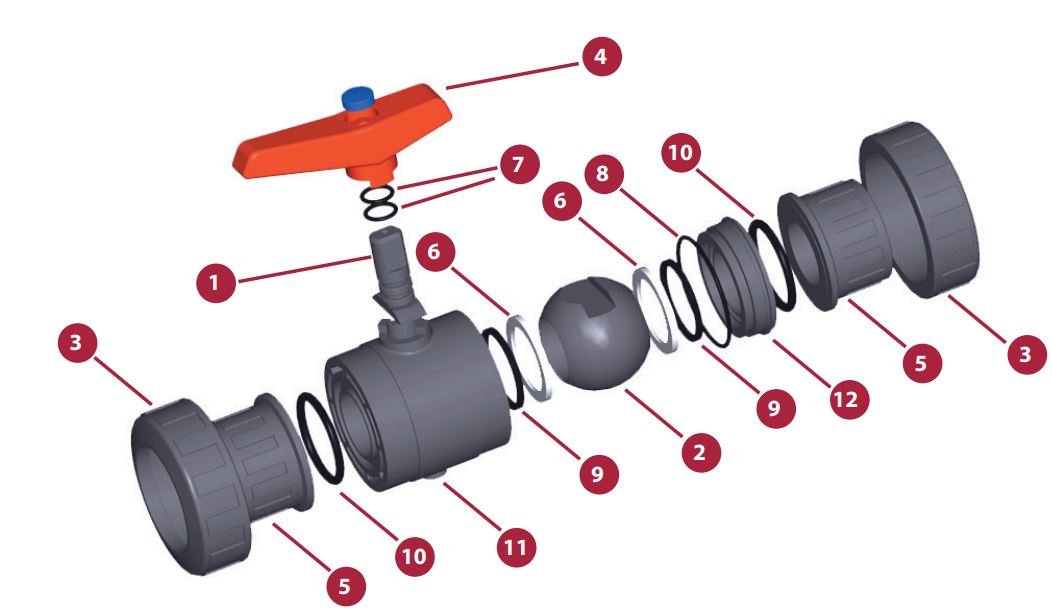

Standard ball valve components

- PVC-U stem

- PVC-U ball

- PVC-U nut

- PP handle assembly

- PVC-U union sleeve

- Ball seat HDPE / PTFE

- Shaft seal EPDM / FPM

- EPDM / FPM body seal

- EPDM / FPM cushioning seal

- EPDM / FPM sleeve seal

- Body PVC-U

- Gasket holder PVC-U

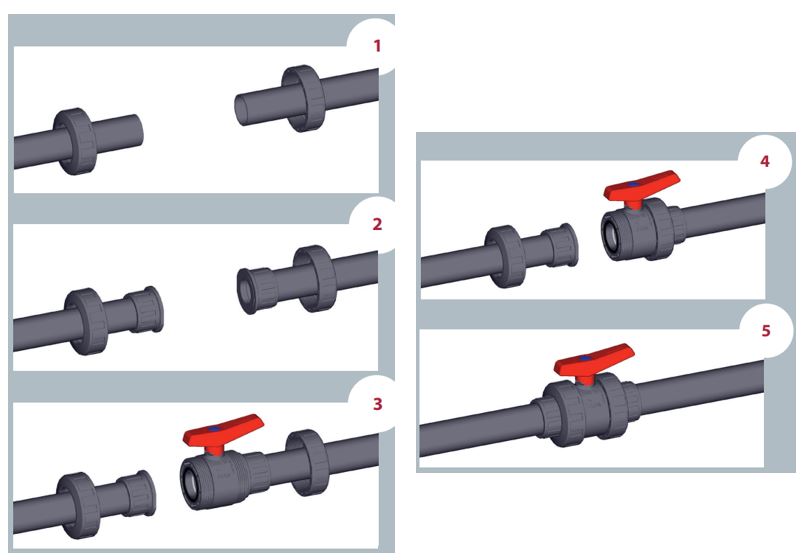

Assembly instructions

- For a correct assembly of the ball valve, follow the instructions below:

- Loosen the nuts on the valve and separate them from the sleeves.

- Insert the nuts into the pipes and fix the sleeves on the pipe ends.

- In the joints to be glued, use adhesive for PVC-U or rigid PVC-C pipes and do not apply pressure until 1 hour per bar.

- In the joints to be threaded, place PTFE tape on the male threads.

- Place the valve between the sleeves and tighten the nuts on the valve.

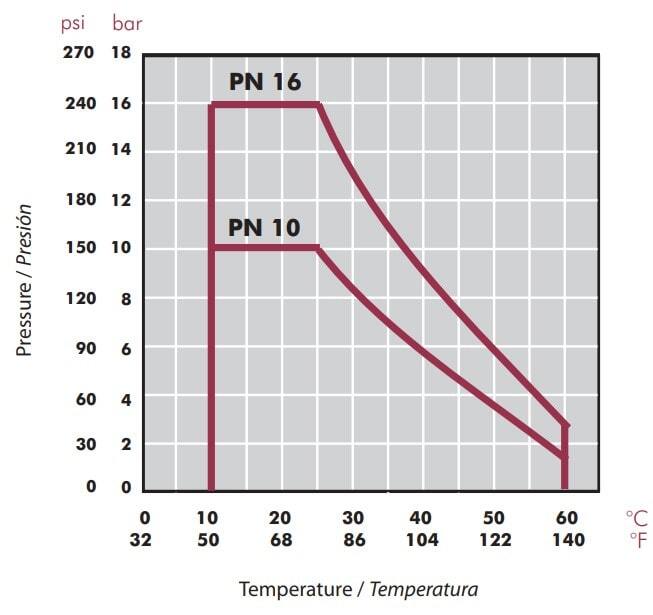

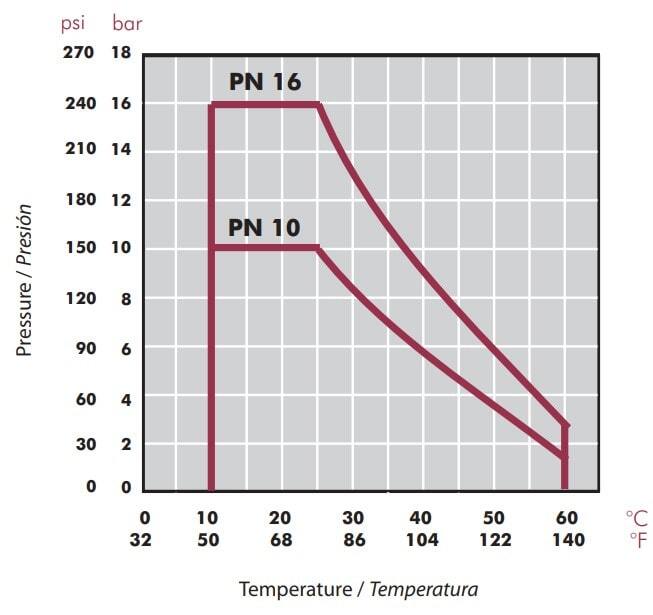

Pressure/temperature diagram