PVC water stopcock

The ball valve or stopcock is the perfect PVC-U accessory to control the water flow and to be able to open and close it when needed.

Cepex offers a complete range of ball valves in different materials (PVC-U , PVC-C) and different lines of valves in different standards (Metric, BSP, ASTM, NPT, JIS) to adapt to the demands and needs of each market.

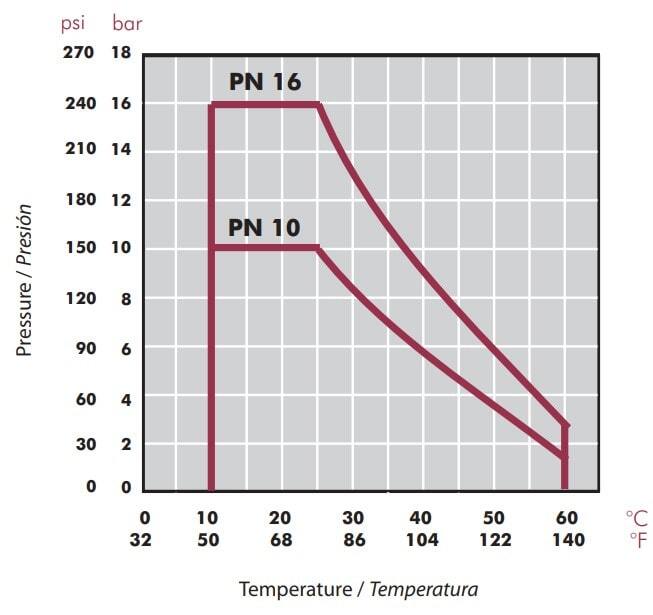

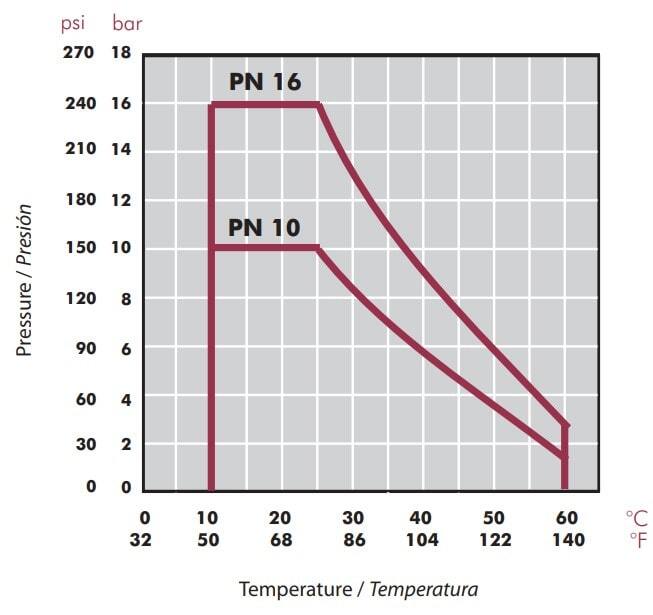

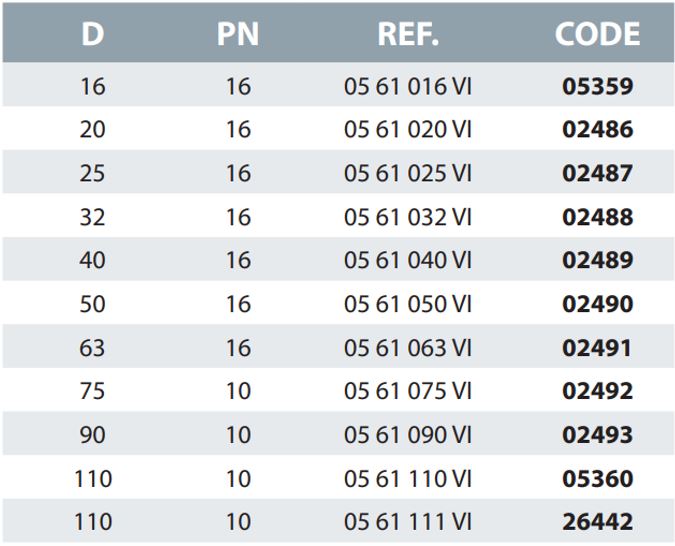

We have a wide range of dimensions and combinations to adapt the installation to your needs from 16 mm diameter up to 110 mm. With nominal pressures of 10 and 16.

Cepex fittings provide both pressure and chemical resistance, allowing their use in water, chemical and waste pipelines, among other sectors.

Features PVC-U ball valves - Standard Series

- Antiblock" system that prevents the ball from blocking.

- 100% factory tested

- Minimal pressure drop

- Low opening and closing torque

- Resistance to multiple inorganic chemicals

- Excellent handling characteristics

Specifications standard glued ball valve

- PVC-U body

- Female socket

- Metric series

- PTFE ball seat seals

- O-rings in FPM (Viton)

- Green label: FPM seals, choose according to the fluid.

Note: It is important to choose the type of valve according to the fluid and therefore to choose between EPDM or FPM (Viton) seals.

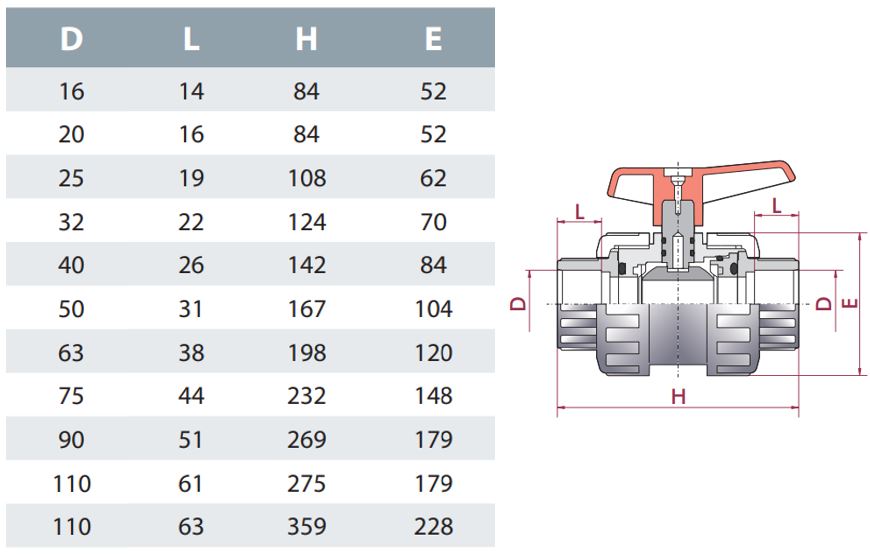

Dimensions of PVC Teflon-FPM ball valve glueing

The following table shows the outer diameter, the normal pressure, and the references of the PVC Teflon-FPM ball valve to be glued:

Consult the following table for the dimensions of the Teflon-FPM PVC ball valve according to the outside diameter.

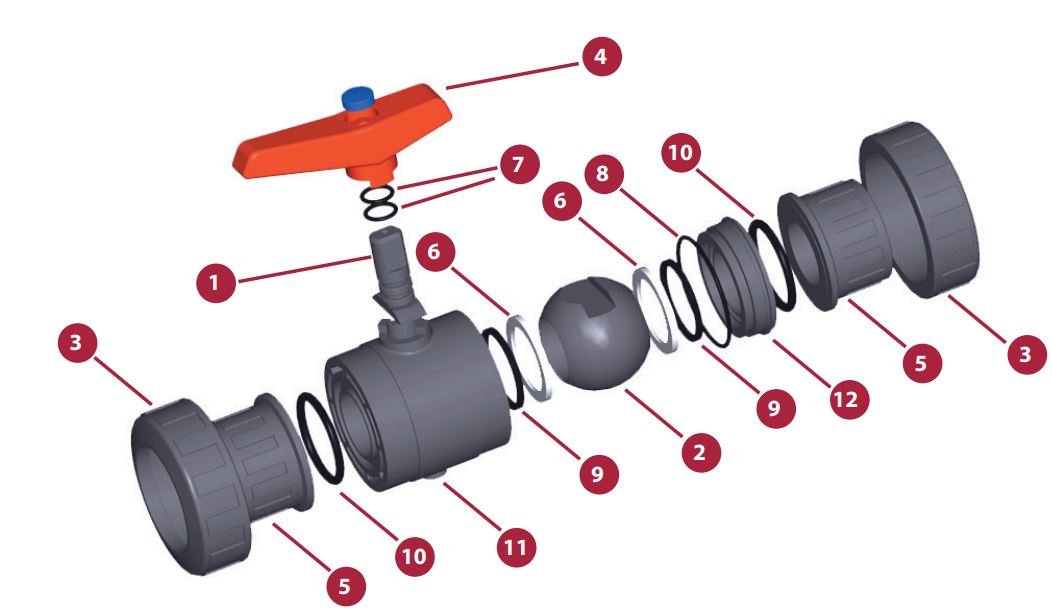

Standard ball valve components

- PVC-U stem

- PVC-U ball

- PVC-U nut

- PP handle assembly

- PVC-U union sleeve

- Ball seat HDPE / PTFE

- Shaft seal EPDM / FPM

- EPDM / FPM body seal

- EPDM / FPM cushioning seal

- EPDM / FPM sleeve seal

- Body PVC-U

- Gasket holder PVC-U

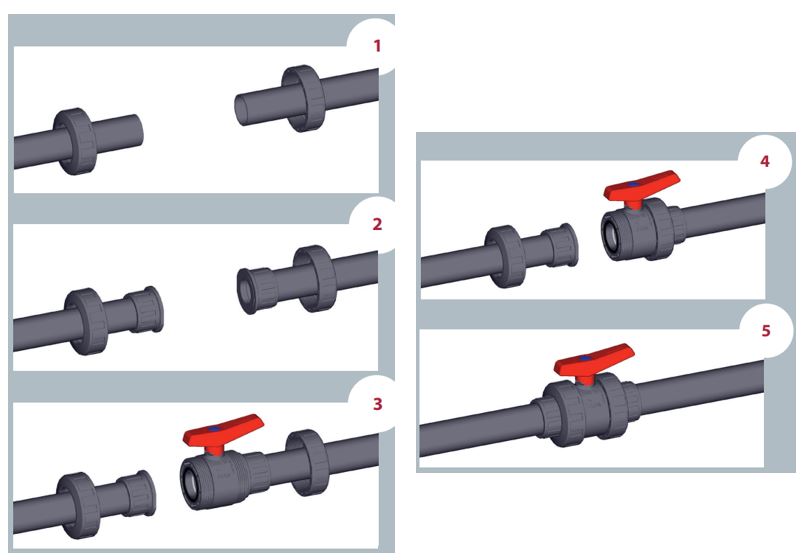

Assembly instructions

- For a correct assembly of the ball valve, follow the instructions below:

- Loosen the nuts on the valve and separate them from the sleeves.

- Insert the nuts into the pipes and fix the sleeves on the pipe ends.

- In the joints to be glued, use adhesive for PVC-U or rigid PVC-C pipes and do not apply pressure until 1 hour per bar.

- In the joints to be threaded, place PTFE tape on the male threads.

- Place the valve between the sleeves and tighten the nuts on the valve.

Pressure/temperature diagram