-DPT 200 VITON seal (FPM): DPT200NHH0000

-DPT 200 EPDM seal: DPT200NHH1000

Seko's line of metering pumps provides versatile solutions for the precise injection of liquids into ducts and pipes, ranging from small pools to large aquatic installations in both indoor and outdoor environments. This equipment can measure a variety of critical parameters such as pH, ORP, conductivity, chlorine, oxygen, turbidity, ozone, bromine, among others, depending on the model selected. Attached to this communication is a comprehensive list detailing the compatibility of the bodies, seals and tubing of the metering pumps with a wide range of chemicals, ensuring efficient and safe performance in the dosing of specific substances.

The Kompact Series features a range of solenoid-driven metering pumps that offer a constant flow rate, regulated by an adjustable dial on the front panel. These pumps ensure optimum performance for a variety of applications and stand out for their exceptional reliability by ensuring chemical compatibility in areas exposed to liquids. With options such as the Kompact DPT 200, equipped with Viton or EPDM seals, it adapts to different application environments according to the user's specific needs.

The pump works in constant mode.

The pump interrupts dosing at 4 mA and doses at a maximum frequency setting when it receives 20 mA.

The pump interrupts dosing at 20 mA and doses at a maximum frequency setting when 4 mA is received.

The pump doses proportionally to an external signal (example: water meter pulse emitter). For each signal received, the pump executes "n" number of programmed strokes. The pump automatically sets the dosing frequency, adapting it to the time between two successive signals.

The pump doses proportionally to an external signal (example: water meter pulse emitter). For each "n" signal received, the pump delivers one stroke.

The pump doses proportionally to an external signal (example: water meter pulse emitter). In this case you can set the quantity to be dosed in mL and the period of time needed to complete the dosing.

The pump doses proportionally to an external signal (example: water meter pulse emitter) by automatically calculating the ratio between the input signal and the pump strokes according to the programmed ppm value.

After receiving the Detonator signal setting, the pump doses an amount that can be programmed in mL. It is possible to set a delay time before dosing (Delay) and a subsequent dosing interval (Interval).

The pump doses a programmed amount in mL. It is possible to set a delay time (Delay) for the pump to start and an interval between subsequent doses (Interval).

10 doses can be programmed for the entire week.

| Model | Pressure | Flow rate | cc/stroke |

Injections/minute |

Connections (mm) |

|

| bar | l/h | Suction | Discharge | |||

| 200 | 10 | 3,0 | 160 | 0,31 | 4/6 | 4/6 |

| 8 | 5,0 | 0,52 | ||||

When selecting the metering pump model or its spare parts, it is essential to take into account the coding found on the side label. This coding not only identifies the model, but also provides crucial information, such as hydraulic characteristics, materials of the different components, power supply...

We consider the model DPT200NHH1000 to explain the coding:

1. The first field corresponds to the model: DPT

2. The second field corresponds to the hydraulic characteristics: 200

3. The third field refers to the voltage of the dosing pumps: N

4. The fourth field refers to the head material: H

5. The fifth field refers to the installation kit: H

6. The sixth field refers to the seals: 1

The seals are crucial components in a dosing pump, and their choice must be based on the nature of the liquid to be dosed. We recommend that you consult the compatibility table to identify the most suitable seals according to the type of liquid you are dosing.

7. The seventh field is standard: 0

![]()

8. The eighth field refers to customizations:00

|

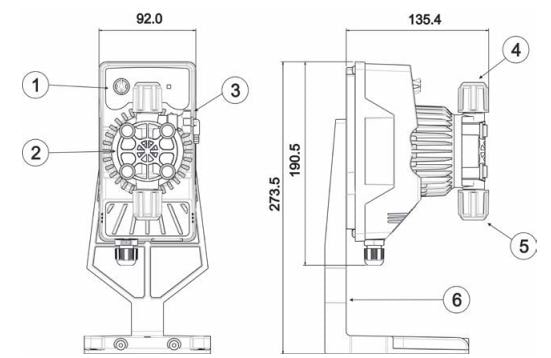

1 | Adjustment area |

| 2 | Dosing head | |

| 3 | Priming valve | |

| 4 | Discharge connection | |

| 5 | Suction fitting | |

| 6 | Mounting bracket |